Khadka Goynta Mashiinka Gariiradda Birta

Ku Takhasusay Khadka Wax-Soosaarka Tubooyinka

In ka badan 23 sano...

Ku habboon farsamaynta qabowga duuban iyo kululaynta birta kaarboonka, birta silikoon, tinplate, birta aan lahayn, iyo dhammaan noocyada kala duwan ee saxanka birta ka dib markii lagu dhejiyo.

Khadka Goynta Mashiinka Gariiradda Birta

Mashiinka Goynta Birta Saxda ah: Xalkaaga Habaynta Gariiradda Waxtarka leh

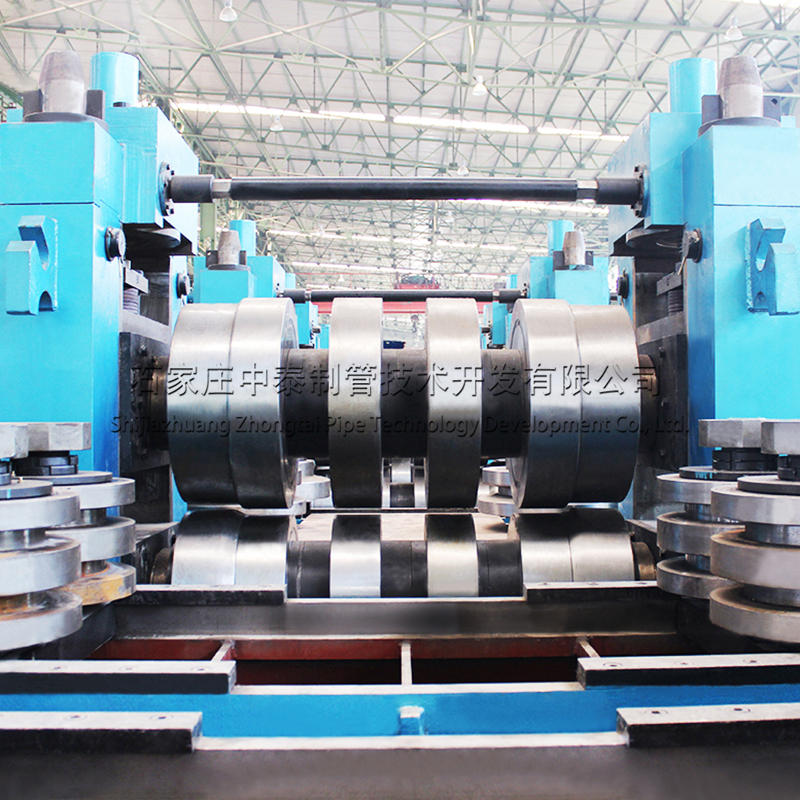

Ourmashiinka wax lagu gooyo birahawaxaa loogu talagalay in si sax ah loo gooyo, jeexjeexo, iyo dib loogu celiyo taarikada birta oo dhowr ah oo dhuuban oo ballac la doonayo. Nidaamkan muhiimka ah wuxuu u beddelaa fiilooyinka birta ballaaran ee ballacyada gaarka ah, diyaarna u ah inuu buuxiyo shuruudaha kala duwan ee wax-soo-saarka tuubooyinka alxanka, wax-soo-saarka qaybta qabow-duuban, iyo codsiyada kale ee hoose.

Tilmaamaha Muhiimka ah iyo Faa'iidooyinka:

- Kala goyn sax ah oo joogta ah:Gaadhi xakamaynta ballaca saxda ah iyo cidhifyada nadiifka ah, adoo hubinaya gariiradaha dhammayska tiran oo tayo sare leh.

- Qalabaynta iyo Dib-u-celinta:Naqshadaynta la hagaajiyay waxay sahlaysa in si siman oo degdeg ah loo maareeyo gariiradaha birta, wanaajinta wakhtiga wax soo saarka.

- Maareynta Walxaha Badan:Awood u leh farsamaynta biraha kala duwan, oo ay ku jiraan kaarboonka birta, birta aan lahayn, iyo aluminium, oo leh dhumucyo kala duwan.

- Balaadhka Jeexitaanka la beddeli karo:Hagaajin ballaca jeexjeexa si aad u buuxiso shuruudaha alaabta gaarka ah, adoo siinaya dabacsanaan codsiyada kala duwan.

- Wax-soo-saarka Hoose ee La xoojiyey:Gariiradaha sida saxda ah loo kala jeexjeexay ayaa ku habboon quudinta hufan oo joogto ah oo lagu shubo tuubooyinka, xadhkaha duubka, iyo hababka kale ee wax soo saarka.

- Dhisme adag oo la isku halayn karo:Lagu dhisay qaybo tayo sare leh oo loogu talagalay waxqabadka muddada dheer iyo dayactirka ugu yar.

Gariiradda-loading - Single-mandrel uncoiler - Gariiradda-madaxa-quudinta, riix & majarafad - Quudinta laba-lullale, saddex rullaluistemadka - Dhammaadka-goynta - Dalool ururinta (1) - Xarig-isku-tagga - xiirashada saxanka - xoqista xoqidda - dalool-uruurinta (2) - Kala-soocidda hore / duubista Dib-u-soo-celinta / gariiradaha saxaafadda & kala-soocida - Gariiradaha-soo daynta - xakamaynta Haydarooliga - Kontoroolka korantada

Macluumaadka Alaabta

| Qaybaha khadka | Uncoiler Leveler Slitter Loop Xiisad Recoiler |

| Qalab | Goosha qabow iyo xaashida GI |

| Ballaca Birta Faleex | 400mm - 2200mm |

| Dhumucda Birta Xarigga | 0.2mm - 20mm |

| Miisaanka | 30.0 T |

| Xoogga Jilicsan | Xoog xajin δb≤500Mpa, Awood soo saar δS≤235Mpa |

| Tirada ugu badan ee Slit | 10 sawir (5mm) 7 sawir (14mm) |

| Saxnaanta Balladhka | ±0.05mm |

| Xawaaraha khadka | 15-60m/daqiiqo |

| Jihada khadka | Codsiga macmiilka |

Waxtarka sare

Xawaaraha khadka wuxuu noqon karaa ilaa 120m/daqiiqo.

Khasaare hooseeya

Khasaaraha halbeegga hooseeya iyo qiimaha wax soo saarka oo hooseeya.

Saxnaanta Sare

Cilada dhexroorku waa 0.5/100 oo kaliya ee tuubada OD.

Codsiga Alaabta

Waxaan u qaabeyn karnaa oo soo saari karnaa mashiinka tuubooyinka si waafaqsan shuruudaha macaamiisha.

Warshadaha Tamarta Cusub

Waddada iyo Buundada

Warshadaha qurxinta dhismaha

Wax kasta oo aad u baahan tahay si aad u abuurto khadka wax soo saarka birta

Shahaadadayada

Shirkadeena

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd. waxaa la aasaasay 2000 oo ku yaala Shijiazhuang, magaalada caasimadda ah ee Gobolka Hebei. Warshada ayaa ku fadhida dhul dhan 67,000 mitir oo laba jibbaaran. alaabta Our ugu muhiimsan ka kooban soo noqnoqda sare line-soo-saarka toosan welded, duudduuban qabow line-soo-saarka birta, multi-function duub qabow birta / line-soosaarka welded, line-soo-saarka jeexjeexay, mishiinka tuubooyinka ahama, qalabka kala duwan ee tuubooyinka tuubooyin gargaare iyo rollers, iwm.

U diyaar ah cusub

Adventure ganacsi?

Hadda la xidhiidh!

| ERW TUBE MILL LINE | |||||

| Qaabka | Rdhuunta dhuunta mm | Squaretuubo mm | Dhumucda mm | Xawaaraha shaqada m/min | |

| ERW20 | Ф8-Ф20 | 6x6-15×15 | 0.3-1.5 | 120 | Sii akhri |

| ERW32 | Ф10-Ф32 | 10×10-25×25 | 0.5-2.0 | 120 | |

| ERW50 | Ф20-Ф50 | 15×15-40×40 | 0.8-3.0 | 120 | |

| ERW76 | Ф32-Ф76 | 25×25-60×60 | 1.2-4.0 | 120 | |

| ERW89 | Ф42-Ф89 | 35×35-70×70 | 1.5-4.5 | 110 | |

| ERW114 | Ф48-Ф114 | 40×40-90×90 | 1.5-4.5 | 65 | |

| ERW140 | Ф60-Ф140 | 50×50-110×110 | 2.0-5.0 | 60 | |

| ERW165 | Ф76-Ф165 | 60×60-130×130 | 2.0-6.0 | 50 | |

| ERW219 | Ф89-Ф219 | 70×70-170×170 | 2.0-8.0 | 50 | |

| ERW273 | Ф114-Ф273 | 90×90-210×210 | 3.0-10.0 | 45 | |

| ERW325 | Ф140-Ф325 | 110×110-250×250 | 4.0-12.7 | 40 | |

| ERW377 | Ф165-Ф377 | 130×130-280×280 | 4.0-14.0 | 35 | |

| ERW406 | Ф219-Ф406 | 170×170-330×330 | 6.0-16.0 | 30 | |

| ERW508 | Ф273-Ф508 | 210×210-400×400 | 6.0-18.0 | 25 | Sii akhri |

| ERW660 | Ф325-Ф660 | 250×250-500×500 | 6.0-20.0 | 20 | Sii akhri |

| ERW720 | Ф355-Ф720 | 300×300-600×600 | 6.0-22.0 | 20 | Sii akhri |

| QADKA SOO SAARINTA TUBEE BIrta AAN AHAYN | |||||

| Qaabka | Rdhuunta dhuunta mm | Squaretuubo mm | Dhumucda mm | Xawaaraha shaqada m/min | |

| SS25 | Ф6-Ф25 | 5×5-20×20 | 0.2-0.8 | 10 | Sii akhri |

| SS32 | Ф6-Ф32 | 5×5-25×25 | 0.2-1.0 | 10 | Sii akhri |

| SS51 | Ф9-Ф51 | 7×7-40×40 | 0.2-1.5 | 10 | Sii akhri |

| SS64 | Ф12-Ф64 | 10×10-50×50 | 0.3-2.0 | 10 | Sii akhri |

| SS76 | Ф25-Ф76 | 20×20-60×60 | 0.3-2.0 | 10 | Sii akhri |

| SS114 | Ф38-Ф114 | 30×30-90×90 | 0.4-2.5 | 10 | Sii akhri |

| SS168 | Ф76-Ф168 | 60×60-130×130 | 1.0-3.5 | 10 | Sii akhri |

| SS219 | Ф114-Ф219 | 90×90-170×170 | 1.0-4.0 | 10 | Sii akhri |

| SS325 | Ф219-Ф325 | 170×170-250×250 | 2.0-8.0 | 3 | Sii akhri |

| SS426 | Ф219-Ф426 | 170×170-330×330 | 3.0-10.0 | 3 | Sii akhri |

| SS508 | Ф273-Ф508 | 210×210-400×400 | 4.0-12.0 | 3 | Sii akhri |

| SS862 | Ф508-Ф862 | 400×400-600×600 | 6.0-16.0 | 2 | Sii akhri |