Soosaarka Warshada Hf Mashiinka Samaynta Dhuumaha, Tuubooyinka Tubada

Anagoo adeegsanayna hal-ku-dheggeena ah "Innovation Tiknoolajiyadu waxay horseedaa heer sare," waxaan noqonay mid ka mid ah kuwa ugu casrisan ee tignoolajiyada, kharash-ku-ool ah, iyo soo-saareyaasha qiimaha lehtuubada tuubadas iyo mashiinada samaynta tuubada ee Shiinaha. Waxaan fahamsanahay muhiimada ugu weyn ee tayada badeecada iyo adeegga, anagoo raacayna falsafada ganacsiga ee "Dadka-Ujeeda, Dhab u ah Dunida, Ku Qanacsanaantaadu waa Raad-raacyadayada." Ma aha oo kaliya in aanu astaysto naqshadaha alaabta ee tuubooyinka tuubooyinka iyomashiinka tuubada samayntas oo ku salaysan muunadaha macaamiisha iyo shuruudo gaar ah si loo daboolo baahiyaha suuqa kala duwan, laakiin sidoo kale waxay bixiyaan xalal shakhsi ahaaneed macaamiisha kala duwan. Waxaan si diiran u soo dhawaynaynaa asxaabta dal iyo dibadba in ay soo booqdaan, ka wada hadlaan iskaashiga, raadiyaan horumar guud, iyo gaarista guul la wada leeyahay!

Sharaxaada

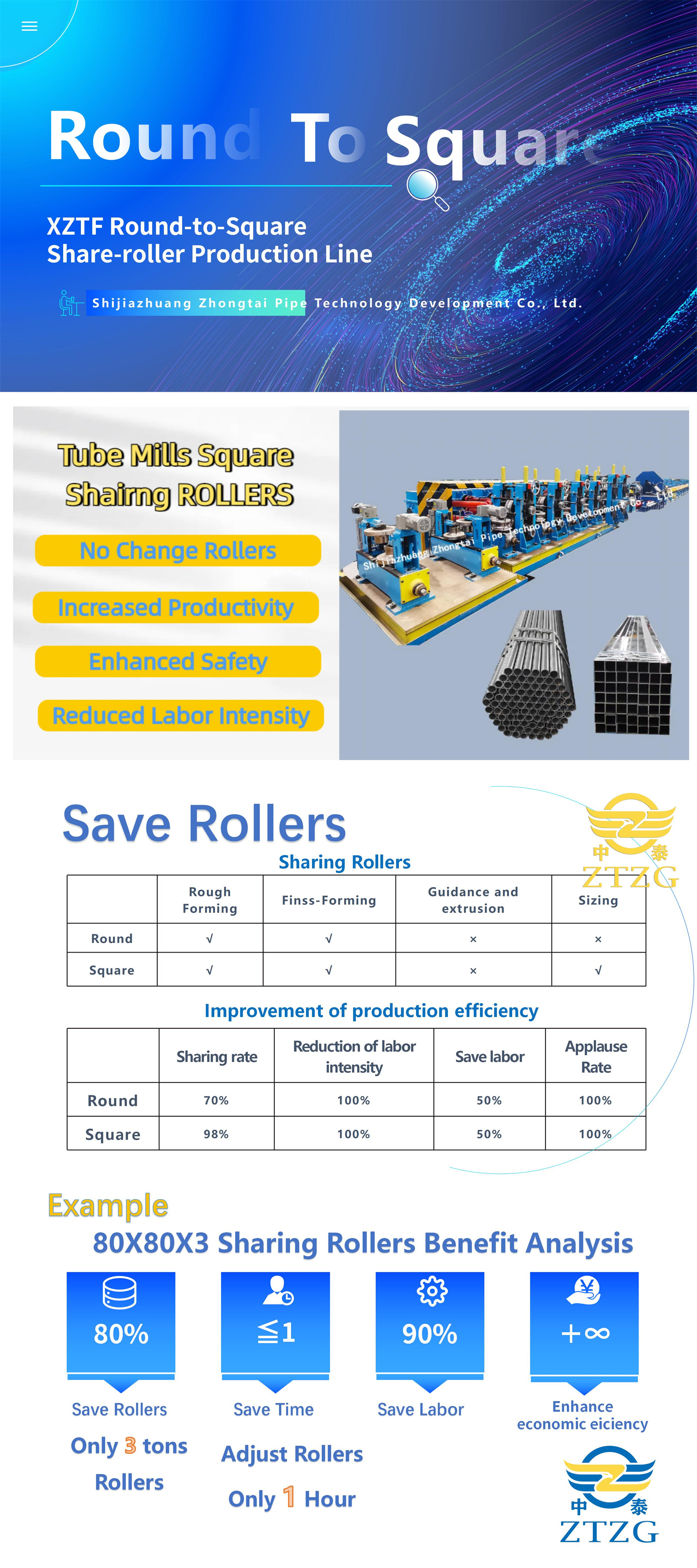

Waxaan ku takhasusay naqshadeynta iyo soo saaristatuubooyinka tuubadaiyomashiinada samaynta tuubada, diiradda saaraya bixinta xalal kharash-ool ah oo la beddeli karo. A sifo kala soocan ourtuubada tuubadawaa naqshadeeda "duubka caadiga ah": tani waxay ka dhigan tahay in duubka loo isticmaalo soo saarista tuubada labajibbaaran iyo leydi leh loo isticmaali karo habka oo dhan iyada oo aan loo baahnayn isbeddelka duubista. Sidoo kale, samaynta tuubooyinka wareega ayaa lagu gaaraa iyada oo aan loo baahnayn in la beddelo ama la beddelo duubista samaynta, taas oo sii fududaynaysa habka wax soo saarka oo aad ku badbaadiso wakhtiga iyo hantida labadaba. Sida hormuudka bixiye eemashiinka tuubada samayntas, waxaan fahamsanahay muhiimada ay leedahay xalal hufan oo la isku halayn karo. Waxaan si diiran kuugu martiqaadeynaa inaad nala soo xiriirto si aad ugala hadasho shuruudahaaga gaarka ah.

Mashiinnada tuubooyinka alxanka leh ee HF oo dhammaystiran waxa ay ka kooban tahay qaybta gelitaanka, qaybta wax-shiidka, qaybta la jaray iyo qaybta dhammaystirka, habka wax-soo-saarka tuubooyinka birta oo ay ku jiraan:

Kor-u-qaadista → Xirxiridda → Xiritaanka iyo Alxanka → Accumulator Spiral → Samaynta → HF Induction Welding → Ka Saaridda Burburka Dibadda → Qaboojinta → Cabbirka → Sawirka Duulimaadka → Miiskii Oo Dhamaaday → Kormeerid → Xidhid → Bakhaarka.

Astaamaha

1.Ku habboon farsamaynta birta kaarboonka

2. Tuubooyinka wareega iyo leydiga ah ayaa lagu soo saari karaa qalabkan

Xawaaraha 3.Production wuxuu gaari karaa ilaa 120m / min

4. Dulqaadashada qaladka dhexroorku waa 0.5/100 ee OD tuubada

macluumaadka alaabta

| Waxsoosaarka & Waxsoosaarka | Dhuumaha Wareegga | 38mm-127mm |

| Labajibaaran & Tube leydi ah | 30x30mm-100x100mm | |

| Dhererka | 6-12m | |

| Xawaaraha wax soo saarka | 50-120m/daqiiqo | |

| Awood-soo-saarka | 5000T | |

| Isticmaalka | Mill rakibay Awood | 300KW-750KW |

| Aagga khadka | 40X5M-80X10m | |

| Shaqaale | 6-8 shaqaale ah | |

| Walxaha ceeriin | Qalab | ST-37 Q345 Q235 |

| Ballaca | 120mm-400mm | |

| Aqoonsiga gariiradda | Φ470 ~ 508mm | |

| Gariiradda OD | Φ1000-1800mm | |

| Miisaanka gariiradda | 2-5Tan |

Faa'iidadayada

1) In ka badan 20 sano oo cilmi-baaris madax-bannaan iyo horumarin iyo waayo-aragnimo wax soo saar. Wuxuu gudbay shahaadada nidaamka tayada ISO9001 wuxuuna ka qayb qaatay diyaarinta tiro heerar warshadeed ah.

2) Taageerada ZTZG sida waafaqsan heerarka caalamiga ah ee gobol kasta, oo bixiya macluumaad farsamo oo joogto ah iyo taageero tababar farsamo.

3) Waxaa jira xakamaynta tayada adag ee alaabta ceeriin, saxnaanta farsamaynta, daaweynta kulaylka, saxnaanta shirarka, qaybaha caadiga ah, iwm. Heerka gudbinta qalabka bixinta waa 100%.

Soo-saarka Warshada Mashiinka Dhuumaha Shiinaha iyo Mashiinka Samaynta Tuubbooyinka, shirkaddu waxay muhiimad weyn u leedahay tayada badeecada iyo adeegga, iyada oo ku saleysan falsafada ganacsiga "ku wanagsan dadka, run ahaantii adduunka oo dhan, ku qanacsanaantaada waa raadintayada". waxaanu naqshadaynaa alaabta, sida waafaqsan shuruudaha macmiilka, si loo daboolo baahiyaha suuqa oo aan siino macaamiil kala duwan oo leh adeeg shakhsi ahaaneed. Shirkaddayadu waxay si diiran u soo dhawaynaysaa asxaabta guriga iyo dibaddaba inay soo booqdaan, si ay uga wada hadlaan iskaashiga iyo raadinta horumarinta guud!

| ERW TUBE MILL LINE | |||||

| Qaabka | Rdhuunta dhuunta mm | Squaretuubo mm | Dhumucda mm | Xawaaraha shaqada m/min | |

| ERW20 | Ф8-Ф20 | 6x6-15×15 | 0.3-1.5 | 120 | Sii akhri |

| ERW32 | Ф10-Ф32 | 10×10-25×25 | 0.5-2.0 | 120 | |

| ERW50 | Ф20-Ф50 | 15×15-40×40 | 0.8-3.0 | 120 | |

| ERW76 | Ф32-Ф76 | 25×25-60×60 | 1.2-4.0 | 120 | |

| ERW89 | Ф42-Ф89 | 35×35-70×70 | 1.5-4.5 | 110 | |

| ERW114 | Ф48-Ф114 | 40×40-90×90 | 1.5-4.5 | 65 | |

| ERW140 | Ф60-Ф140 | 50×50-110×110 | 2.0-5.0 | 60 | |

| ERW165 | Ф76-Ф165 | 60×60-130×130 | 2.0-6.0 | 50 | |

| ERW219 | Ф89-Ф219 | 70×70-170×170 | 2.0-8.0 | 50 | |

| ERW273 | Ф114-Ф273 | 90×90-210×210 | 3.0-10.0 | 45 | |

| ERW325 | Ф140-Ф325 | 110×110-250×250 | 4.0-12.7 | 40 | |

| ERW377 | Ф165-Ф377 | 130×130-280×280 | 4.0-14.0 | 35 | |

| ERW406 | Ф219-Ф406 | 170×170-330×330 | 6.0-16.0 | 30 | |

| ERW508 | Ф273-Ф508 | 210×210-400×400 | 6.0-18.0 | 25 | Sii akhri |

| ERW660 | Ф325-Ф660 | 250×250-500×500 | 6.0-20.0 | 20 | Sii akhri |

| ERW720 | Ф355-Ф720 | 300×300-600×600 | 6.0-22.0 | 20 | Sii akhri |

| QADKA SOO SAARINTA TUBEE BIrta AAN AHAYN | |||||

| Qaabka | Rdhuunta dhuunta mm | Squaretuubo mm | Dhumucda mm | Xawaaraha shaqada m/min | |

| SS25 | Ф6-Ф25 | 5×5-20×20 | 0.2-0.8 | 10 | Sii akhri |

| SS32 | Ф6-Ф32 | 5×5-25×25 | 0.2-1.0 | 10 | Sii akhri |

| SS51 | Ф9-Ф51 | 7×7-40×40 | 0.2-1.5 | 10 | Sii akhri |

| SS64 | Ф12-Ф64 | 10×10-50×50 | 0.3-2.0 | 10 | Sii akhri |

| SS76 | Ф25-Ф76 | 20×20-60×60 | 0.3-2.0 | 10 | Sii akhri |

| SS114 | Ф38-Ф114 | 30×30-90×90 | 0.4-2.5 | 10 | Sii akhri |

| SS168 | Ф76-Ф168 | 60×60-130×130 | 1.0-3.5 | 10 | Sii akhri |

| SS219 | Ф114-Ф219 | 90×90-170×170 | 1.0-4.0 | 10 | Sii akhri |

| SS325 | Ф219-Ф325 | 170×170-250×250 | 2.0-8.0 | 3 | Sii akhri |

| SS426 | Ф219-Ф426 | 170×170-330×330 | 3.0-10.0 | 3 | Sii akhri |

| SS508 | Ф273-Ф508 | 210×210-400×400 | 4.0-12.0 | 3 | Sii akhri |

| SS862 | Ф508-Ф862 | 400×400-600×600 | 6.0-16.0 | 2 | Sii akhri |