Mashiinka Tuubada Birta φ406×14 ;ZTFIV;ZTZG

Sharaxaada

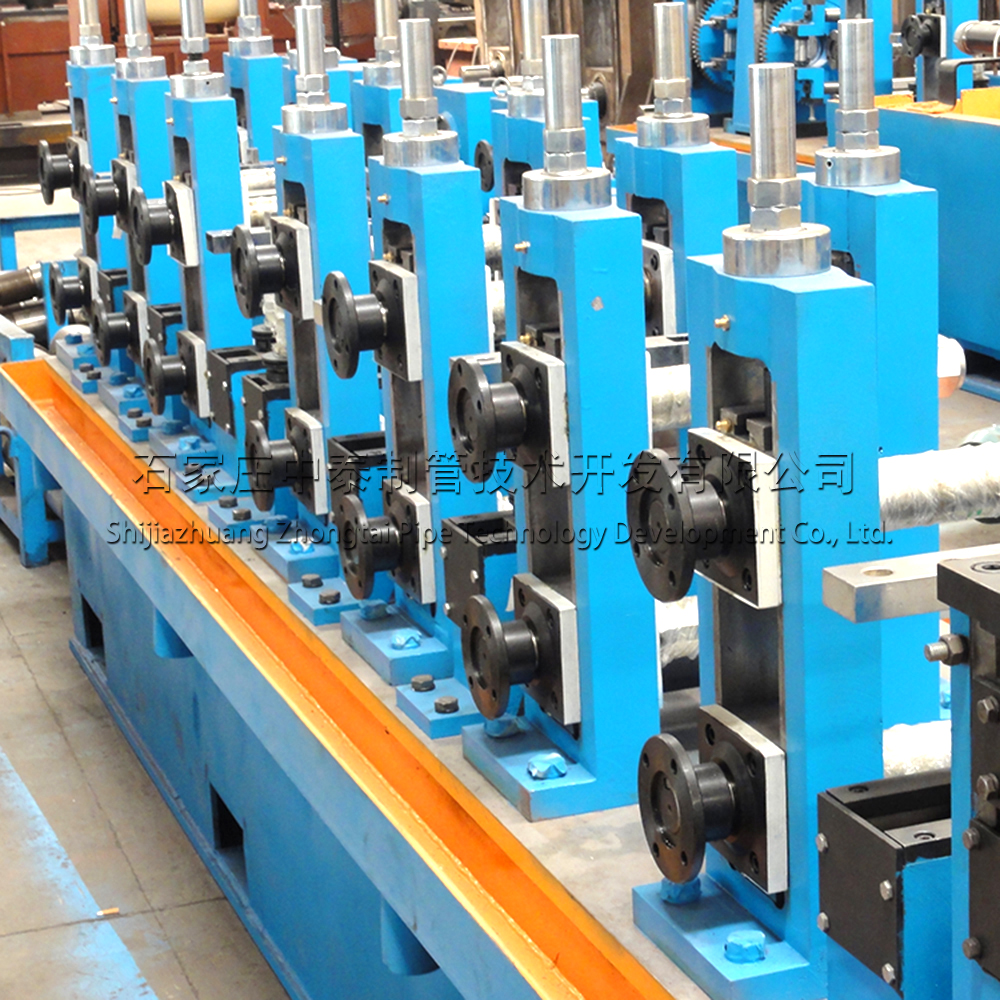

Mashiinnada tuubada ERW waxa kale oo loo yaqaan khadka soo saarista tuubooyinka dhererka-soo noqnoqda sare leh. Qalabka ku habboon waa gariiradaha fidsan ee kulul ama qabow-duuban sida birta kaarboonka caadiga ah iyo birta xoogga badan, iwm.

Birta xariijimaha ah waxaa furaya gawaaruhu, ka dibna waxa uu galaa kaydinta kaydinta ka dib marka uu dhex maro mishiinka alxanka dabada xiiran. Birta xariijimaha ah waxaa lagu soo saaraa rollers waxayna u qaybsan tahay laba qaybood: qaybta jajabinta iyo qaybta gudbinta ganaaxa. Ka dib alxanka soo noqnoqda ee soo noqnoqda iyo qaybta cabbirka, soo saar dhererka loo baahan yahay ee tuubada, gooya miinshaar duulaya, oo ugu dambeyntii raso oo xir tuubada birta ah. Khadka wax-soo-saarkani waa khad wax-soo-saar dhammaystiran oo dhammaystiran oo loogu talagalay alxanka joogtada ah ee fiilooyinka birta ee tuubooyinka,inta badan ka kooban gariiriye, dhogorta & dhamaadka alxanka, ururiye, samaynta & mashiinka cabbirka, alxanka HF, miinshaar duulaya, mashiinka wax lagu dhejiyo & baakadaha.

Haddii ay jiraan ujeedooyin gaar ah ama shuruudo loogu talagalay tuubooyinka birta, waxaa lagama maarmaan ah in lagu daro qalabka baaritaanka, sida mashiinka tijaabinta hydraulic, mishiinka soo noqnoqda dhexdhexaadka ah, mashiinka ogaanshaha cilladda ultrasonic, iwm.

Khadka wax soo saarka ee inta jeer ee welded High waxaa inta badan loo isticmaalaa wax soo saarka joogtada ah ee tolmo toosan welded. Waxay qabataa alxanka induction soo noqnoqda ee soo noqnoqda, kaas oo aan soo saari karin oo keliya tuubo wareegsan laakiin sidoo kale tuubooyinka labajibbaaran ee u dhigma iyo tuubooyinka qaabaysan gaarka ah. Mashiinka alxanka tuubooyinka heerka sarreeya ayaa inta badan loo isticmaalaa soo saarista tuubooyinka birta ee kala duwan, tuubooyinka dhismaha, tuubooyinka qaab dhismeedka, tuubooyinka biyaha, tuubooyinka saliidda, tuubooyinka API, iyo wixii la mid ah.

Tsocodka farsamada

Duubista → Xiritaanka → Shear iyo alxanka → Samaynta alxanka induction → Samaynta → HF induction alxanka → Burinta dibadda → Qaboojinta → Cabbirka → miinshaar duulaya → Miis ka baxay

Fhabka diyaarinta

| Dhuumaha wareega | Habka samaynta duubka qabow | Naqshadaynta rullaluistemadka wanaagsan |

| Habka samaynta ZTF | Ku keydi ugu yaraan 60% kharashka rullaluistuyada leh hagaajinta kontoroolka korantadaSii akhri | |

| Tuubo laba geesood ah & leydi ah | Habka wareega-ilaa-square ee guud | Habka samaynta xasilloon |

| Wareeg-ilaa-square oo leh madax Turki ah | Tayada tuubada wanaagsan | |

| Habka tooska ah labajibbaaran-ilaa-square (DSS) | Hal rullale ah ayaa soo saari kara dhammaan tuubooyinka leh kontoroolka koronto iyo hagaajin toos ahSii akhri |

Macluumaadka Farsamo ee Aasaasiga ah ee Khadka Wax-soo-saarka Tubooyinka Welded

| Badeecada & Waxsoosaarka | Dhuumaha Wareegga | 219mm-406Dhumucda mm:6.0mm-16.0mm |

| Labajibaaran & Tube leydi ah | 170mm×170mm -330mm×330Dhumucda mm:6.0mm-16.0mm | |

| Dhererka | 6m-12m Dulqaadka Dhererka: ± 3mm | |

| Xawaaraha wax soo saarka | 30m/min | |

| Awood-soo-saarka | 180,000ton/sannad | |

| Isticmaalka | Mill rakibay Awood | 880 kw |

| Aagga khadka | 160m (dhererka) ×16m (ballac) | |

| Shaqaale | 6-8 shaqaale ah | |

| Walxaha ceeriin | Qalab | Gariiradda Birta Kaarboon Q235B(ASTM GR·D,σs 230) |

| Ballaca | 690mm-1280Dhumucda mm:4.0mm-16.0mm | |

| Aqoonsiga gariiradda | 580-760mm | |

| Gariiradda OD | Max2300mm | |

| Miisaanka gariiradda | 35.0t |

Faa'iidada

Faa'iidooyinka qalabka:

Marka la soo saarayo tuubo wareegsan, waxay isticmaali kartaa farsamada samaynta ZTF

Marka la soo saarayo tubbada labajibbaaran & leydi leh, waxay isticmaali kartaa si toos ah farsamada labajibbaaran (DSS)

Alaabta:Tuubooyinka qaab dhismeedka qaab dhismeedka, tuubooyinka API, tuubooyinka taawarada, tuubooyinka birta birta ah ee baabuurta iyo alaabada kale.

| ERW TUBE MILL LINE | |||||

| Qaabka | Rdhuunta dhuunta mm | Squaretuubo mm | Dhumucda mm | Xawaaraha shaqada m/min | |

| ERW20 | Ф8-Ф20 | 6x6-15×15 | 0.3-1.5 | 120 | Sii akhri |

| ERW32 | Ф10-Ф32 | 10×10-25×25 | 0.5-2.0 | 120 | |

| ERW50 | Ф20-Ф50 | 15×15-40×40 | 0.8-3.0 | 120 | |

| ERW76 | Ф32-Ф76 | 25×25-60×60 | 1.2-4.0 | 120 | |

| ERW89 | Ф42-Ф89 | 35×35-70×70 | 1.5-4.5 | 110 | |

| ERW114 | Ф48-Ф114 | 40×40-90×90 | 1.5-4.5 | 65 | |

| ERW140 | Ф60-Ф140 | 50×50-110×110 | 2.0-5.0 | 60 | |

| ERW165 | Ф76-Ф165 | 60×60-130×130 | 2.0-6.0 | 50 | |

| ERW219 | Ф89-Ф219 | 70×70-170×170 | 2.0-8.0 | 50 | |

| ERW273 | Ф114-Ф273 | 90×90-210×210 | 3.0-10.0 | 45 | |

| ERW325 | Ф140-Ф325 | 110×110-250×250 | 4.0-12.7 | 40 | |

| ERW377 | Ф165-Ф377 | 130×130-280×280 | 4.0-14.0 | 35 | |

| ERW406 | Ф219-Ф406 | 170×170-330×330 | 6.0-16.0 | 30 | |

| ERW508 | Ф273-Ф508 | 210×210-400×400 | 6.0-18.0 | 25 | Sii akhri |

| ERW660 | Ф325-Ф660 | 250×250-500×500 | 6.0-20.0 | 20 | Sii akhri |

| ERW720 | Ф355-Ф720 | 300×300-600×600 | 6.0-22.0 | 20 | Sii akhri |

| QADKA SOO SAARINTA TUBEE BIrta AAN AHAYN | |||||

| Qaabka | Rdhuunta dhuunta mm | Squaretuubo mm | Dhumucda mm | Xawaaraha shaqada m/min | |

| SS25 | Ф6-Ф25 | 5×5-20×20 | 0.2-0.8 | 10 | Sii akhri |

| SS32 | Ф6-Ф32 | 5×5-25×25 | 0.2-1.0 | 10 | Sii akhri |

| SS51 | Ф9-Ф51 | 7×7-40×40 | 0.2-1.5 | 10 | Sii akhri |

| SS64 | Ф12-Ф64 | 10×10-50×50 | 0.3-2.0 | 10 | Sii akhri |

| SS76 | Ф25-Ф76 | 20×20-60×60 | 0.3-2.0 | 10 | Sii akhri |

| SS114 | Ф38-Ф114 | 30×30-90×90 | 0.4-2.5 | 10 | Sii akhri |

| SS168 | Ф76-Ф168 | 60×60-130×130 | 1.0-3.5 | 10 | Sii akhri |

| SS219 | Ф114-Ф219 | 90×90-170×170 | 1.0-4.0 | 10 | Sii akhri |

| SS325 | Ф219-Ф325 | 170×170-250×250 | 2.0-8.0 | 3 | Sii akhri |

| SS426 | Ф219-Ф426 | 170×170-330×330 | 3.0-10.0 | 3 | Sii akhri |

| SS508 | Ф273-Ф508 | 210×210-400×400 | 4.0-12.0 | 3 | Sii akhri |

| SS862 | Ф508-Ф862 | 400×400-600×600 | 6.0-16.0 | 2 | Sii akhri |