100% Asalkii Toosan Wareega Wareega Laba geesoodka Tuubbada Mashiinka alxanka Soo noqnoqoshada Sare

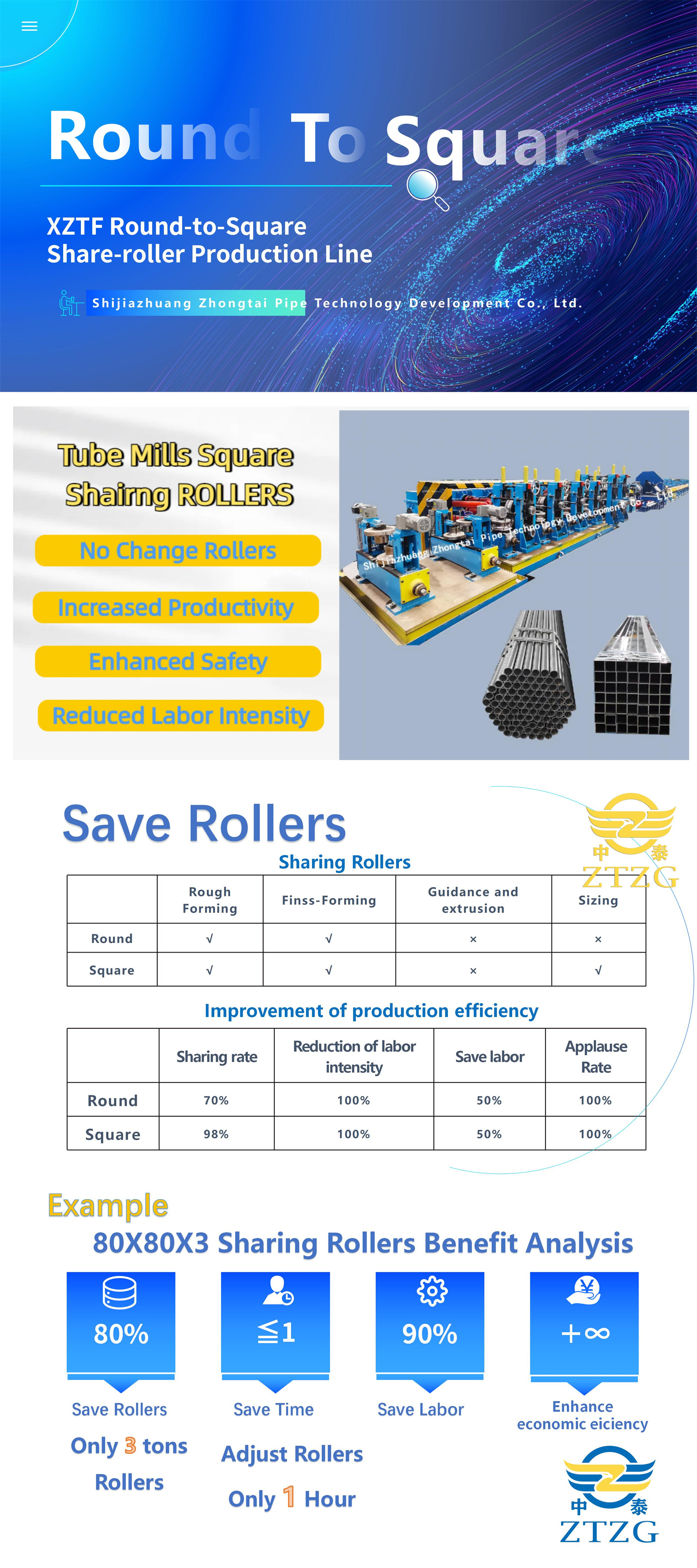

Soo saarista tuubooyinka wareega ee ZTZGTuubbada Mills: Wax soo saarka tuubooyinka wareega waxay ka faa'iidaystaan rollers-ka la wadaago qaybta samaynta, iyada oo yaraynaysa isbeddelada qalabaynta ee ourtuubada tuubadaline. Hagaajinta waxaa lagu fududeeyaa kontaroolada korantada ama otomaatiga ah. Qaybta cabbirka, rullaluistuyada si degdeg ah ayaa loo beddelaa iyadoo la isticmaalayo nidaamka gawaarida dhinac-jiidista ah.

Wax-soo-saarka Pipe ee Square ee ZTZGTuubbada Mills: Si la mid ah wax soo saarka tuubooyinka wareegsan, qaybtayada samaynta tuubooyinka labajibbaaran waxay ka faa'iideysanayaan rolalka la wadaago. Rollers-kan la wadaago si fudud ayaa loo hagaajin karaa iyadoo la isticmaalayo kontaroolo koronto ama otomaatik ah.

Sharaxaada

ERW (Alxanka Iska caabinta Korontada)TubeMillayaa sidoo kale loo yaqaanKhadka wax soo saarka ee tuubooyinka alxanka dheer ee soo noqnoqonaya. Qalabka ku habboon waa gariiradaha fidsan ee kulul ama qabow-duuban sida birta kaarboonka caadiga ah iyo birta xoogga badan, iwm.

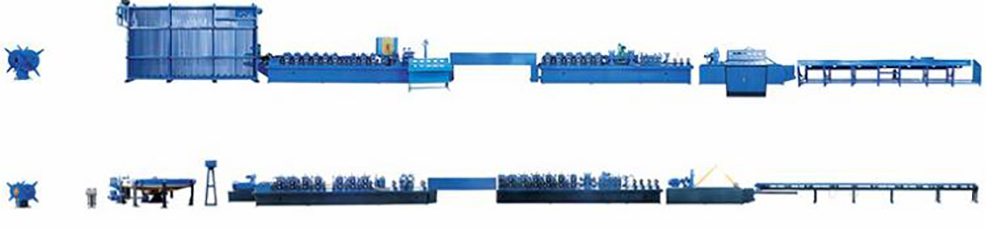

Birta xariijimaha ah waxaa furaya gawaaruhu, ka dibna waxa uu galaa kaydinta kaydinta ka dib marka uu dhex maro mishiinka alxanka dabada xiiran. Birta xariijimaha ah waxaa lagu soo saaraa rollers waxayna u qaybsan tahay laba qaybood: qaybta jajabinta iyo qaybta gudbinta ganaaxa. Ka dib alxanka soo noqnoqda ee soo noqnoqda iyo qaybta cabbirka, soo saar dhererka loo baahan yahay ee tuubada, gooya miinshaar duulaya, oo ugu dambeyntii raso oo xir tuubada birta ah. Khadka wax-soo-saarkani waa khad wax-soo-saar dhammaystiran oo dhammaystiran oo loogu talagalay alxanka joogtada ah ee fiilooyinka birta ee tuubooyinka,inta badan ka kooban uncoiler,dhogorta & dhamaadka alxanka,ururiye,samaynta & mashiinka cabbirka,alxanka HF,miinshaar duulaya,mashiinka wax lagu dhejiyo & baakadaha.

Haddii ay jiraan ujeedooyin gaar ah ama shuruudo loogu talagalay tuubooyinka birta, waxaa lagama maarmaan ah in lagu daro qalabka baaritaanka, sida mashiinka tijaabinta hydraulic, mishiinka soo noqnoqda dhexdhexaadka ah, mashiinka ogaanshaha cilladda ultrasonic, iwm.

Habka wax soo saarka birta:

Duubista → xiirid iyo alxanka → Accumulator → Samaynta → HF Induction Welding → Burka Dibadeed saarista → Qaboojinta → Cabbirka → Wax arka Duulida → Miis ka baxay

Astaamaha:

1.Ku habboon farsamaynta GI, birta kaarboon iyo tuubooyinka birta madow, iwm.

2. Tuubooyinka wareega iyo leydiga ah ayaa lagu soo saari karaa qalabkan

Xawaaraha 3.Production wuxuu gaari karaa ilaa 120m / min

4. Dulqaadashada qaladka dhexroorku waa 0.5/100 ee OD tuubada

macluumaadka alaabta

Faa'iidada

In ka badan 20 sano oo cilmi-baaris madax-bannaan iyo horumarin iyo waayo-aragnimo wax soo saar. Wuxuu gudbay shahaadada nidaamka tayada ISO9001 wuxuuna ka qayb qaatay diyaarinta tiro heerar warshadeed ah.

Taageerada ZTZG si waafaqsan heerarka caalamiga ah ee gobol kasta, oo bixiya macluumaad farsamo oo joogto ah iyo taageero tababar farsamo.

Waxaa jira xakamaynta tayada adag ee alaabta ceeriin, saxnaanta farsamaynta, daaweynta kulaylka, saxnaanta isu imaatinka, qaybaha caadiga ah, iwm. Heerka gudbinta qalabka bixinta waa 100%.

| ERW TUBE MILL LINE | |||||

| Qaabka | Rdhuunta dhuunta mm | Squaretuubo mm | Dhumucda mm | Xawaaraha shaqada m/min | |

| ERW20 | Ф8-Ф20 | 6x6-15×15 | 0.3-1.5 | 120 | Sii akhri |

| ERW32 | Ф10-Ф32 | 10×10-25×25 | 0.5-2.0 | 120 | |

| ERW50 | Ф20-Ф50 | 15×15-40×40 | 0.8-3.0 | 120 | |

| ERW76 | Ф32-Ф76 | 25×25-60×60 | 1.2-4.0 | 120 | |

| ERW89 | Ф42-Ф89 | 35×35-70×70 | 1.5-4.5 | 110 | |

| ERW114 | Ф48-Ф114 | 40×40-90×90 | 1.5-4.5 | 65 | |

| ERW140 | Ф60-Ф140 | 50×50-110×110 | 2.0-5.0 | 60 | |

| ERW165 | Ф76-Ф165 | 60×60-130×130 | 2.0-6.0 | 50 | |

| ERW219 | Ф89-Ф219 | 70×70-170×170 | 2.0-8.0 | 50 | |

| ERW273 | Ф114-Ф273 | 90×90-210×210 | 3.0-10.0 | 45 | |

| ERW325 | Ф140-Ф325 | 110×110-250×250 | 4.0-12.7 | 40 | |

| ERW377 | Ф165-Ф377 | 130×130-280×280 | 4.0-14.0 | 35 | |

| ERW406 | Ф219-Ф406 | 170×170-330×330 | 6.0-16.0 | 30 | |

| ERW508 | Ф273-Ф508 | 210×210-400×400 | 6.0-18.0 | 25 | Sii akhri |

| ERW660 | Ф325-Ф660 | 250×250-500×500 | 6.0-20.0 | 20 | Sii akhri |

| ERW720 | Ф355-Ф720 | 300×300-600×600 | 6.0-22.0 | 20 | Sii akhri |

| QADKA SOO SAARINTA TUBEE BIrta AAN AHAYN | |||||

| Qaabka | Rdhuunta dhuunta mm | Squaretuubo mm | Dhumucda mm | Xawaaraha shaqada m/min | |

| SS25 | Ф6-Ф25 | 5×5-20×20 | 0.2-0.8 | 10 | Sii akhri |

| SS32 | Ф6-Ф32 | 5×5-25×25 | 0.2-1.0 | 10 | Sii akhri |

| SS51 | Ф9-Ф51 | 7×7-40×40 | 0.2-1.5 | 10 | Sii akhri |

| SS64 | Ф12-Ф64 | 10×10-50×50 | 0.3-2.0 | 10 | Sii akhri |

| SS76 | Ф25-Ф76 | 20×20-60×60 | 0.3-2.0 | 10 | Sii akhri |

| SS114 | Ф38-Ф114 | 30×30-90×90 | 0.4-2.5 | 10 | Sii akhri |

| SS168 | Ф76-Ф168 | 60×60-130×130 | 1.0-3.5 | 10 | Sii akhri |

| SS219 | Ф114-Ф219 | 90×90-170×170 | 1.0-4.0 | 10 | Sii akhri |

| SS325 | Ф219-Ф325 | 170×170-250×250 | 2.0-8.0 | 3 | Sii akhri |

| SS426 | Ф219-Ф426 | 170×170-330×330 | 3.0-10.0 | 3 | Sii akhri |

| SS508 | Ф273-Ф508 | 210×210-400×400 | 4.0-12.0 | 3 | Sii akhri |

| SS862 | Ф508-Ф862 | 400×400-600×600 | 6.0-16.0 | 2 | Sii akhri |